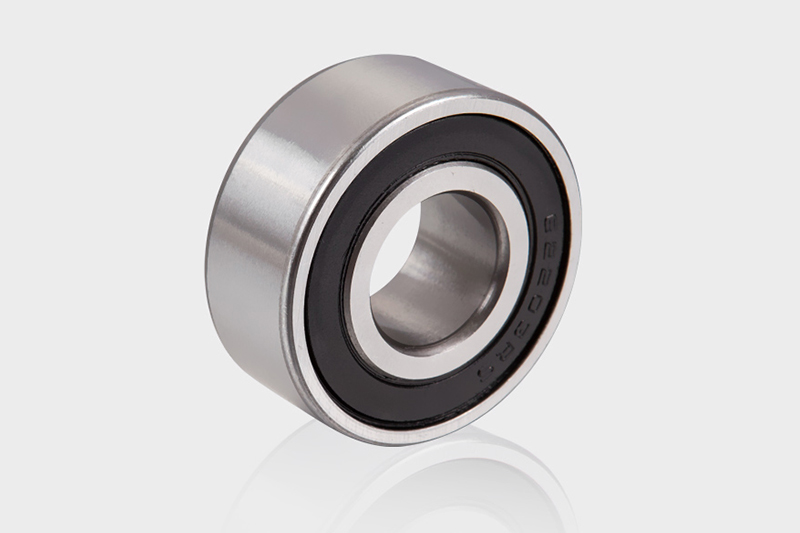

Angular contact ball bearings are integral components in machinery that require precise control over radial and axial loads. Their design, featuring balls positioned at an angle between the inner and outer races, allows them to handle both types of loads simultaneously. The various types of angular contact ball bearings are specifically designed to meet different performance and load requirements.

What is an Angular Contact Ball Bearing?

An angular contact ball bearing is designed to support combined loads, i.e., both radial and axial (thrust) loads, in one direction. This is achieved by having the contact angle between the balls and the races, typically between 15° and 40°. The load is applied to the bearing at an angle, which allows the bearing to withstand axial loads from one direction, along with radial loads. These bearings are especially useful in high-speed applications, such as in spindles, electric motors, and machine tools, where both types of loads are typically experienced.

Angular contact bearings can be configured in different ways to meet specific requirements. The design and arrangement of these bearings, such as the number of rows of balls, the contact angle, and the bearing arrangement, determine how the bearing will perform under various conditions.

1. Single Row Angular Contact Ball Bearings

Description :

Single row angular contact ball bearings are the simplest and most common type. They feature a single row of balls between the inner and outer races. The angle of contact typically ranges from 15° to 40°, depending on the specific application. These bearings are typically designed to carry axial loads in one direction in addition to radial loads.

Specific Uses :

- High-Speed Machines : These bearings are ideal for applications that require high-speed operation, such as in electric motors, gearboxes, and machine spindles. The single row configuration allows for reduced friction, making them suitable for applications that require smooth, fast operation.

- Machine Tool Spindles : In applications like CNC machines, the precision and high-speed capabilities of single row bearings make them crucial for maintaining the accuracy and efficiency of the spindles.

- Pumps and Compressors : Single row angular contact ball bearings are used in pumps and compressors where both radial and axial loads need to be handled effectively, while maintaining speed and performance.

| Key Features | Benefits | Common Applications |

|---|---|---|

| Single row design | Cost-effective and space-saving | High-speed machinery |

| Angle between 15° to 40° | Efficient at handling radial and axial loads | Electric motors, CNC machines |

| Reduced friction | Suitable for smooth operation | Pumps, compressors |

2. Double Row Angular Contact Ball Bearings

Description :

Double row angular contact ball bearings consist of two rows of balls, which allows them to handle larger axial loads than single row bearings. These bearings can support axial loads in both directions, making them more versatile. The contact angles in double row bearings are generally between 30° and 40°, enabling them to support higher loads compared to single-row variants.

Specific Uses :

- Heavy Load Applications : Double row bearings are ideal for heavy machinery and equipment, such as cranes, conveyors, and steel mills, where both radial and axial loads need to be handled simultaneously. They can also withstand larger axial forces without compromising the bearing’s integrity.

- Electric Motors : In electric motors where high torque is generated, double row angular contact bearings offer the necessary support for both radial and axial loads.

- Industrial Gearboxes : Double row bearings are commonly used in industrial gearboxes where large axial forces are present, as they offer increased load capacity and stability over single row designs.

Applications and Features :

Double row angular contact ball bearings are best suited for applications requiring high load capacity, both for radial and axial loads. Their ability to handle large axial loads makes them perfect for heavy-duty machines.

| Key Features | Benefits | Common Applications |

|---|---|---|

| Two rows of balls | Increased load capacity | Heavy machinery, electric motors |

| Contact angle between 30° and 40° | Can handle higher axial loads | Industrial gearboxes, cranes |

| Higher radial and axial load tolerance | Provides stability in extreme conditions | Steel mills, conveyors |

3. Back-to-Back (DB) Angular Contact Ball Bearings

Description :

Back-to-back (DB) angular contact ball bearings consist of two single row bearings arranged with their outer races facing each other, forming a “V” shape. This configuration allows the bearing to handle both radial and axial loads from both directions, providing a stable and reliable setup. The angle of contact in DB bearings is typically between 30° and 40°.

Specific Uses :

- High-Precision Applications : Back-to-back angular contact bearings are ideal for applications requiring high precision and the ability to withstand axial loads from multiple directions. This is common in industries such as aerospace and robotics.

- Differential Gears : In automotive applications, DB bearings are commonly used in differential gears, where they can handle the combined radial and axial loads exerted during operation.

- Machine Tools : For applications in CNC machines, where high levels of axial load control and precision are required, DB bearings are preferred due to their ability to stabilize axial forces from both sides.

| Key Features | Benefits | Common Applications |

|---|---|---|

| “V” shaped back-to-back design | Handles axial loads from both directions | High-precision machinery |

| Contact angles between 30° and 40° | Stable performance under axial forces | Automotive differentials |

| Increased rigidity | Ensures precision and reliability | CNC machines, robotics |

4. Face-to-Face (DF) Angular Contact Ball Bearings

Description :

In a face-to-face (DF) angular contact ball bearing, two single-row bearings are arranged such that their inner races face each other. This arrangement is compact but generally has a lower axial load capacity than back-to-back configurations. The DF design is typically used when space is limited but axial load handling is still necessary.

Specific Uses :

- Compact Systems : Face-to-face bearings are used in applications where space is constrained but axial load handling is still required. These bearings are commonly used in small motors and low-load systems.

- Electric Motors : For small electric motors where moderate axial and radial load handling is necessary, face-to-face angular contact ball bearings offer a good balance of performance and compact size.

- Low-Load Applications : These bearings are perfect for systems with lower load demands, such as fans, small pumps, and basic industrial machines.

| Key Features | Benefits | Common Applications |

|---|---|---|

| Compact face-to-face design | Space-saving design for limited spaces | Small electric motors |

| Suitable for lower axial loads | Cost-effective in low-load scenarios | Fans, basic industrial machinery |

| Moderate radial and axial load capacity | Efficient for small systems | Small pumps, low-load applications |

5. Tandem (DT) Angular Contact Ball Bearings

Description :

Tandem (DT) angular contact ball bearings consist of two single-row bearings arranged in series. The contact angles are aligned in the same direction, and these bearings are designed to handle unidirectional axial loads effectively.

Specific Uses :

- Unidirectional Axial Loads : Tandem bearings are ideal for applications where large axial loads are applied in one direction, such as in heavy-duty electric motors or turbine generators.

- Wind Turbine Gearboxes : The tandem configuration is often used in wind turbine gearboxes, where large axial loads are common.

- Large Machine Tools : These bearings are also used in large machines where concentrated axial forces in one direction are prevalent, such as in metalworking and grinding equipment.

| Key Features | Benefits | Common Applications |

|---|---|---|

| Two bearings arranged in series | Handles large axial loads in one direction | Wind turbines, turbine generators |

| Aligned contact angles | Optimized for heavy axial load handling | Large machine tools |

| High axial load capacity | Ideal for unidirectional forces | Heavy-duty electric motors |

FAQ (Frequently Asked Questions)

1. What is the difference between single row and double row angular contact ball bearings?

Single row bearings have one row of balls and are suitable for handling smaller axial loads in one direction, while double row bearings have two rows of balls and can handle larger axial loads in both directions.

2. Can angular contact ball bearings handle both radial and axial loads?

Yes, angular contact ball bearings are specifically designed to handle both radial and axial loads simultaneously, making them ideal for high-speed and high-precision applications.

3. What does the contact angle of an angular contact ball bearing indicate?

The contact angle refers to the angle between the line of contact of the balls and the bearing axis. A larger contact angle allows the bearing

to handle higher axial loads, whereas a smaller angle is better suited for higher speed applications.

4. How do I choose the right angular contact ball bearing for my application?

Consider factors such as the load type (radial and axial), speed, precision requirements, and available space. Double row and back-to-back configurations are ideal for higher loads, while single row bearings are suitable for high-speed applications.

5. What industries commonly use angular contact ball bearings?

Angular contact ball bearings are commonly used in industries like aerospace, automotive, machine tools, robotics, and energy production, especially in applications that require high precision, speed, and load handling.

References

- Angular Contact Bearings Overview . (2022). Bearing Information Guide .

- Selecting Angular Contact Ball Bearings for Industrial Applications . (2021). Industrial Bearing Technology .

- High-Speed and High-Load Bearings for Precision Machinery . (2020). Machine Tool Engineering .

- Bearing Designs for Heavy-Duty Applications . (2023). Heavy Equipment Bearings Manual .