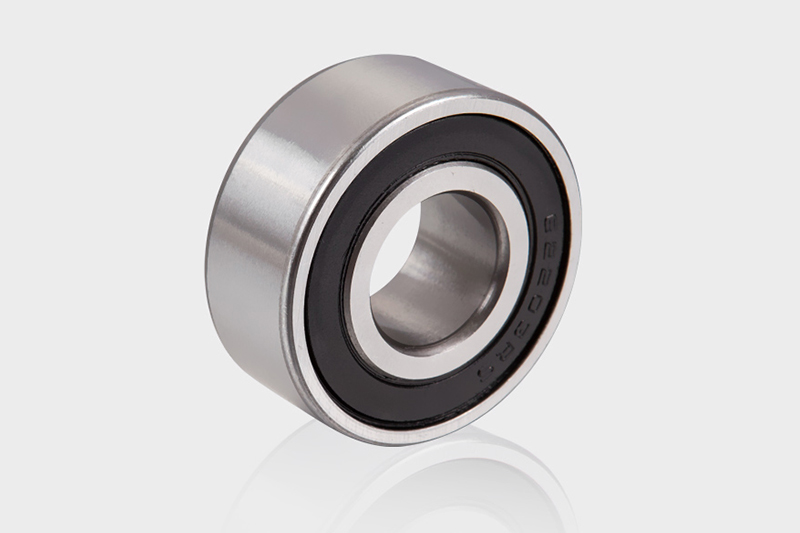

Insert Bearings are a widely used but often underestimated key component in industrial machinery. Many people think that they are just a bearing seat added to the outside of ordinary bearings, and their actual function is limited. After a deeper understanding, you will find that Insert Bearings are not only ingenious in structure, but also show many unexpected advantages in practical applications, especially in equipment installation, operation stability and post-maintenance.

From the perspective of structural design, Insert Bearings have good self-aligning ability. This self-adjusting function enables the bearing to automatically adapt to slight deviations during installation. Even if there is a certain bend in the axis or the fixation is not precise, it can operate normally without jamming or abnormal wear. This feature greatly improves the fault tolerance rate and reduces equipment failures caused by installation errors. It is one of the important factors to ensure the long-term stable operation of equipment.

In terms of installation convenience, Insert Bearings show significant advantages. Compared with traditional bearings that require precise matching and complex positioning, they mostly use simplified designs such as set screws, eccentric sleeves or sleeve fixation, which not only reduces the installation steps, but also reduces the requirements for the professional level of technicians. This convenience is particularly valuable on industrial sites, especially when quick replacement or emergency repairs are required, which can greatly reduce downtime and improve production efficiency.

Insert Bearings also demonstrate excellent performance in maintenance management. Many models are pre-filled with grease at the factory and equipped with a special oiling hole. Users can maintain good lubrication of the bearings by regular oiling without frequent disassembly and cleaning. Its sealing design is also better, effectively preventing dust, moisture and other contaminants from entering the interior of the bearing, extending the service life and reducing the frequency of maintenance.

Insert Bearings also perform well in impact resistance and environmental adaptability. Because they form a stable integrated structure with the bearing seat, they can effectively disperse pressure and reduce impact when subjected to loads from all directions, which helps to improve the fatigue resistance of the entire system. Whether in high dust, high humidity, or in an environment with drastic temperature changes, Insert Bearings can work stably. Some products are even made of corrosion-resistant stainless steel or coated, which is particularly suitable for food processing, chemical equipment, agricultural machinery and other application scenarios with special environmental requirements.